Role of Vapor Smoothing in Manufacturing 3D Printed Parts

Ever wondered how manufacturers get those super smooth finishes on 3D printed parts? Or how they turn raw prints into pro-grade products? The answer is vapor smoothing. This advanced post-processing technique not only removes visible layer lines but also improves mechanical properties and durability. From consumer goods to medical devices, vapor smoothing is the new […]

FDA Polymer Coating: Enhancing Safety & Durability

Do your custom parts fail under harsh conditions? From rust and wear to chemical exposure, these common problems can quickly compromise the integrity and performance of your parts. FDA polymer coatings provide a solution by adding an extra layer of protection for your parts.More corrosion resistance, abrasion resistance, and environmental damage means your custom parts […]

Sheet Metal Bending Techniques: Basics to Advanced Methods

How do industries like aerospace and automotive push the boundaries of design and durability? The answer is mastering sheet metal bending. It’s not just about bending sheet metal — it’s about creating stronger, lighter, more efficient components that drive innovation.In this guide, we’ll uncover advanced sheet metal bending techniques, explore cutting-edge tools, and tackle advanced […]

6 Specialized 3D Printing Materials that are Trending

Why would you go beyond the basic 3D printing materials? After all, PLA and ABS do the job for most standard projects. Plus, they’re cheap, easy to work with, and get the job done most of the time. But when a project comes along that requires specific features—like extra strength, heat resistance, or flexibility you […]

Metal Curling in Custom Manufacturing: Techniques, Tools, and Trends

In custom manufacturing, metal curling is a process of rolling or bending the edges of metal parts to increase strength and appearance. This process not only reinforces edges to prevent deformation but also removes sharp corners, making components safer to handle, especially in high-performance applications. But what are the best ways to incorporate curling into […]

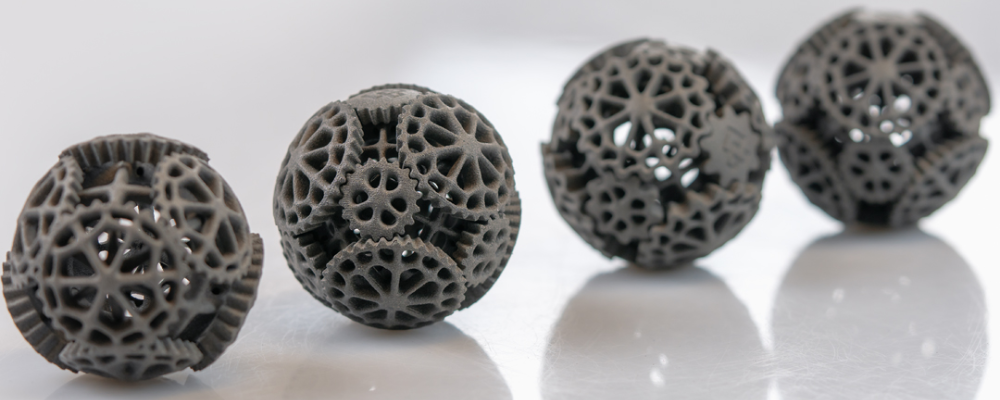

Advanced Applications of MJF 3D Printing in Mass production

How can manufacturers streamline production while meeting the growing demand for customization and speed? The answer lies in advanced Multi Jet Fusion (MJF) 3D printing. It can transform high-volume manufacturing by overcoming the limitations of traditional 3D printing methods. With MJF, you can produce complex geometries fast, eliminate tooling costs, and get a great surface […]

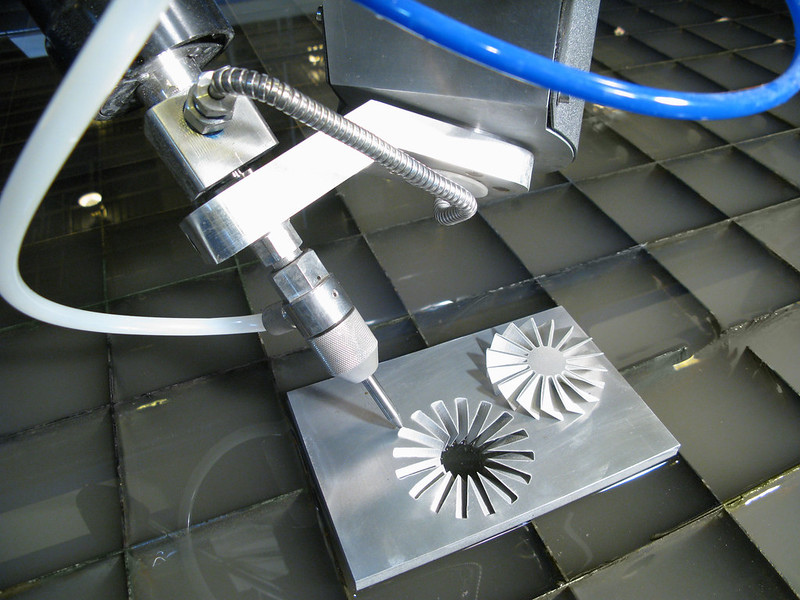

Advanced CNC Machining Techniques for Marine Applications

Marine applications face challenges like harsh saltwater conditions and the need for high precision in custom parts. Accuracy is crucial for ensuring that parts perform reliably in these tough environments. But what happens when you’re dealing with tight deadlines or managing a high volume of work orders? Especially for high-precision parts? Balancing accuracy with timely […]

Challenges and Solutions in Vacuum Casting for High-Performance Components

You chose vacuum casting for your project because it offers incredible precision and a smooth finish, which is perfect for the detailed components, right? However, despite its many advantages, vacuum casting does come with its own set of challenges. From dealing with air bubbles and maintaining dimensional accuracy to managing costs and ensuring a flawless […]

Quality Control in Injection Molding: Best Practices for Manufacturing Engineers

Quality control in injection molding is essential. Without it, even small defects can turn into big problems, leading to wasted materials, costly rework, and unhappy customers. For manufacturing engineers, getting quality control right is all about catching issues early and ensuring every part meets the mark. This guide is here to help you do just […]

How Does EDM Wire Cutting Work

Shaping tough materials like tungsten carbide or hardened steel is challenging for traditional machining methods. These methods often struggle with precision and efficiency, leading to tool wear and limited capabilities. EDM (Electrical Discharge Machining) solves this problem by using electrical discharges to erode the material, enabling precise cutting of even the toughest materials. And this […]