Carbides are carbon-based compounds melded with metals known for their exceptional hardness, brittleness, and high melting points. Because of their versatility, carbides, from cutting tools to coatings and abrasives, are used across industries. Carbide-cutting tools, such as drills, end mills, etc, are widely used in CNC machining to cut through tough materials and create precise mechanical parts. The commonly used carbides in manufacturing mechanical parts are:

Titanium Carbide is a hard ceramic material with a high melting point (3160°C). It has a low coefficient of friction and good thermal conductivity. It is also used as an abrasion-resistant surface coating on metal parts, such as tool bits.

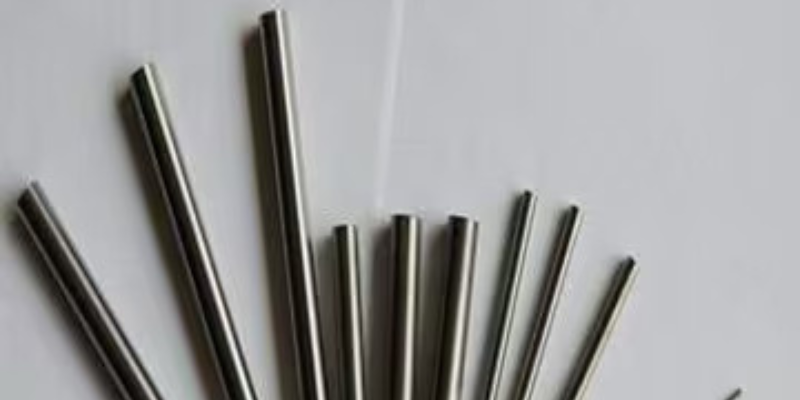

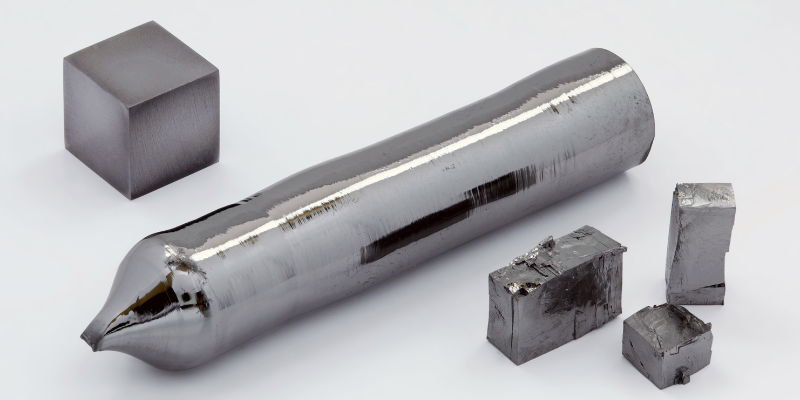

Tungsten Carbide is a hard and dense material known for its exceptional hardness and wear resistance. Because of their high melting point and excellent thermal conductivity, these are used in cutting tools, drills, inserts, and wear parts in machining.

Tantalum Carbide is a hard refractory material known for its excellent hardness and chemical inertness. It can withstand high temperatures. Tantalum carbide is a hard coating material for cutting tools, dies, and wear parts in machining.

Niobium Carbide is a hard refractory ceramic material commercially used in tool bits for cutting tools. This carbide is commonly included as a grain growth inhibitor in cemented carbides.